Plate and frame filter press (also known as plate and frame filter) is a commonly used filter. The filter medium is fabric, and filter aid is added during filtration. The commonly used filter aid is diatomite, so it is also called diatomite. The filter is a plate and frame type diatomite filter. The plate and frame filter can be used in two types, one is the common use of filter plate (or filter cloth) as the filter medium, the other is the use of filter paper and a layer of Diatomaceous earth was used as filter medium.

The name plate and frame filter is named because the device is composed of alternating plates and frames. The effect of the plate is to support the filter medium and collect the filter cake, and the effect of the filter frame in between is to transport the liquid Distributed to the entire surface of the filter medium. This type of equipment is equipped with multiple sets of plates and frames, each plate (or frame) has a common input channel to input wine, that is, one input channel can distribute wine to all plates ( or box). Any part of the wine flows through the filter only once, adding plates, and the number of sets of boxes can increase the production capacity of this filter.

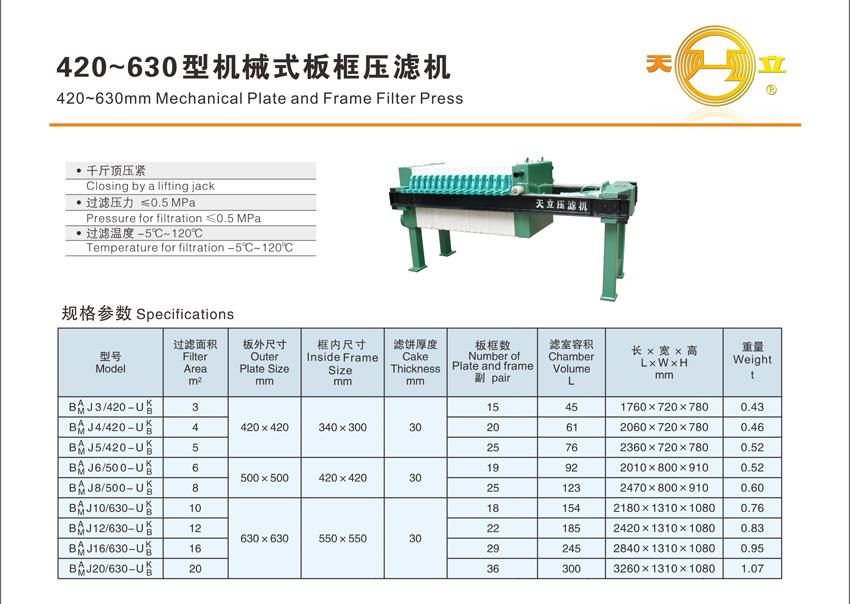

These plates and frames are generally rectangular and hang on the support rods on two sides. The sealing effect of the plate and frame is completed by the pressing of two end plates, and the movable end plate at one end is equipped with a pressing winch. The selected The size and number of plates (and frames) determine the filtering area of the filter, and the number of plates and frames can be easily adjusted. The degree of clarity of the liquid to be treated is confirmed by the grade of diatomaceous earth or filter plate. For coarse filtration , Generally, filter plates with a flow rate of 20004000L\/(㎡.h) are used, and for finer filter media, the flow rate can be reduced to 800-2000L\/(㎡.h) under a pressure drop of 100200kPa.

The thrust plate and the machine base are connected by two longitudinal beams to form a frame, and a pressing plate is placed on one end of the frame near the pressing device. The filter frame and the filter plate are alternately placed between the thrust plate and the pressing plate. , The filter cloth is sandwiched between the filter frame and the filter plate. After pressing, a filter chamber is formed between the filter frame and the two filter cloths. The filter cloth medium also has a sealing effect to prevent leakage between the contact surface of the filter frame and the filter plate. The cloth is cotton or synthetic fiber industrial filter cloth, the size should be larger than the outer size of the plate frame, the density and the number of layers are determined by the material liquid. The two sides of the filter plate and the filter frame are provided with lifting lugs, which are hung on the two longitudinal beams when installed. The filter frame is hollow, and there are grooves on the surface of the two sides of the filter plate. There are small holes in the upper right corner of the filter plate and the filter frame. After installation, these small holes form the slurry filter channel. There are also small holes on the filter frame. The filtrate enters the filter plate through the filter cloth during filtration, and the filter residue is deposited on the filter cloth to form a filter cake in the frame.

下一条: No Information

Related News

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- These follow-up work should be done after the filter press is shut down