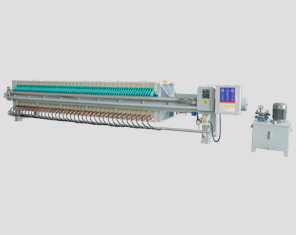

Can the filter press be left alone after it is shut down? In fact, it is not so simple. Langdong Chemical reminds that the following follow-up operations must be done after the shutdown to ensure the normal use of the equipment next time.

1. When the filter press equipment is working intermittently, the basic operation is to make sure that there is no filtrate in the equipment, which means that there can be no inferior filtrate in the equipment, because the filtrate in the intermittent condition is gradually air-dried in the equipment. When they accumulate, they will form solid solids one by one, which will not only block important parts of the equipment, but may also cause the filter press to fail to operate normally when it is restarted next time. In severe cases, the filter press will burst. Therefore, it is necessary to use the The filtrate is washed out of the equipment to prevent them from drying out in the equipment or chemically altered.

2. Once the filter cloth of the filter press is used, it is necessary to preserve the wetness of the filter cloth, because now once the filter cloth and the filter press are used together, the strong pressure of the filtrate and the equipment can make the filter cloth produce Wonderful change, such a filter cloth can no longer withstand the dry test. Because the filter cloth is dried out, it will cause the shrinkage of the filter cloth fibers, so that the filter cloth will be severely changed in the quality of blocking solid particles, and the filter cloth will be severely changed. It will seriously affect the working quality of the filter press, and it will also make the filter cloth more easily damaged, so the protection of the filter cloth should be done after the shutdown.

3. After the filter press equipment works intermittently, it is necessary to prevent the hydraulic station from entering the water, otherwise it will cause the oil to deteriorate and rot, so the sealing protection of the hydraulic station should be done after the shutdown.

The shutdown operation should not be careless, which directly affects the service life of the equipment and the efficiency of the next operation. We cannot ignore the follow-up operation, and the operation after the shutdown should be given equal attention to the protection and maintenance.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Diaphragm filter presses should regularly check the use of filter plates

- Features of automatic filter press

- 3 practical filter press failure analysis and solutions

- What is the 2nd press of a diaphragm filter press

- What should I do if the pressure of the automatic filter press cannot be reached?

- Maintenance and maintenance of blower in environmental protection sewage treatment equipment?

- What is the operating principle of the double-stage filter? What is the difference between it and the traditional filter?

- The prospect and development trend of diatomite filter

- The use of the filter plates of the diaphragm filter press should be checked regularly

- What should I do if the frame of the plate cardboard filter is deformed? Learn these tricks to solve it easily