In the hydraulic system of the diaphragm filter, when it touches the hydraulic system of the plate and frame filter press, the part that cannot be sealed is the hydraulic equipment. Since the hydraulic equipment adopts the double-cylinder and screw extension structure, if there is a slight problem with the double-cylinder piston seal, or the screw If the gap between the arm and the bottom nozzle is 1mm, the sealing effect of the hydraulic system will be reduced, which will not only cause a lot of hydraulic oil to overflow, but also cause enough pressure in the hydraulic system to affect the operation of the entire equipment.

Diaphragm filter press filter room, I believe that as long as anyone has seen a horizontal filter press, they will know the extremely important part of the plate and frame filter press - the filter room, which is an independent independent filter plate. The filter is arranged in the center , and then the device supplies strong pressure to make them enter the filter chamber. It is primarily responsible for filtering separation. When it works, it is full of filtrate, and their internal energy is still high. If there is a small area in the filter chamber, it cannot be Sealing, this is enough to cause the internal pressure of the filter chamber to be insufficient. High, causing the filtrate to flow in the normal filtering path, and then affecting the operating efficiency and quality of the equipment. In addition, the continuous infiltration of the filtered liquid into the unsealed place not only reduces the operation of the equipment quality, and increase the uselessness of the equipment, resulting in waste of equipment. Therefore, it can be seen that in order to make the filter press equipment work normally, the filter chamber needs to be sealed.

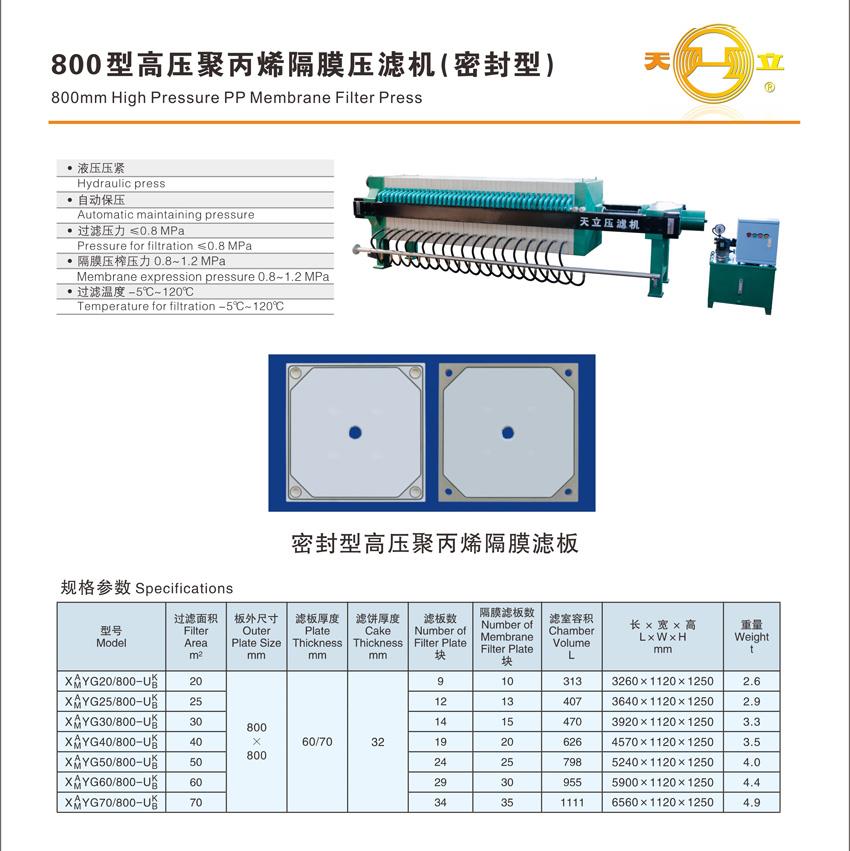

Diaphragm filter press has the advantages of high limit pressure, good corrosion resistance, convenient maintenance and high reliability. The main difference from the general box filter press is that 2 elastic membranes are added on the 2 sides of the filter plate (the composite rubber membrane is the whole membrane). During the operation process, when the feeding is completed, the high-pressure fluid medium is injected into The membrane plate is expanded and the entire membrane is expanded to filter the filter cake to achieve further dehydration of the filter cake, which is pressure filtration.

The diaphragm filter press plate adopts the central feed separation tube, which has obvious advantages, that is, a diaphragm filter press can be formed during the filtration process, and the formed filter cake can be uniformly formed in the center of the filter plate and is very shaped. After the diaphragm filter press 2 times of kneading to complete the finishing. If the half-width feed separation tube is used, not only the irregularity of the filter cake composition is added, but also the feed amount is reduced, which then affects the efficiency of the membrane filter press. Membrane filter press The filtration process of high-efficiency dehydration is realized, which can ensure that the filter filter achieves excellent filtration effect and greatly reduces the moisture content of the filter cake. After the feeding process is completed, the filter cake is pressed to improve the dehydration efficiency of the whole machine. Dryness, reduced pollution, reduced labor, and even in some processes, the drying process can be eliminated. If blowing operations are added before and after the restriction, the moisture content of the filter cake can be further reduced.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- The development trend of filter press in the domestic environmental protection profession

- The difference between diaphragm filter press and ordinary box filter press

- How to improve the working efficiency of the filter press?

- Super essential oil filter is easy to operate, safe and low energy consumption

- The difference between high pressure plate and frame filter press and high pressure diaphragm filter press