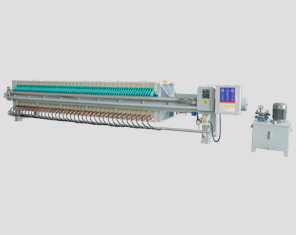

The main difference between the diaphragm filter press and the ordinary box filter press is that a layer of elastic membrane diaphragm plate is installed between the filter plate and the filter cloth. During operation, when the feeding ends, the high-pressure fluid medium can be removed. It is injected between the filter plate and the diaphragm, and the entire diaphragm will start to press the filter cake, and then complete the further dehydration of the filter cake, which is the pressing filtration.

The first is positive pressure dehydration, also known as slurry dehydration, that is, a certain number of filter plates are closely arranged in a row under the effect of strong mechanical force, and a filter chamber is formed between the filter plate surface and the filter plate surface. It is sent into the filter chamber under positive pressure. The solid part of the filter material entering the filter chamber is retained by the filter medium (such as filter cloth) to form a filter cake. The liquid part passes through the filter medium and is discharged from the filter chamber, and then achieves the purpose of solid-liquid separation With the increase of positive pressure, the solid-liquid separation is more thorough, but from the perspective of energy and cost, too high positive pressure is not cost-effective.

After slurry feeding and dehydration, a filter press equipped with a rubber kneading membrane, the compression medium (such as gas, water) enters the reverse side of the kneading membrane to push the kneading membrane to further dehydrate the kneading filter cake, which is called kneading dehydration. After dehydration or kneading and dehydration, the compressed air enters the filter cake side of the filter chamber to penetrate the filter cake, and carries liquid water from the other side of the filter cake through the filter cloth to discharge the filter chamber for dehydration, which is called wind blowing dehydration. If the filter chamber 2 There are filter cloths on the sides, and the liquid part can evenly pass through the filter cloth on the side of the filter chamber 2 and be discharged from the filter chamber to dewater the filter chamber on both sides.

After the dehydration is completed, the mechanical pressing force of the filter plate is released, the filter plate is gradually pulled apart, and the filter chamber is opened separately to unload the cake as a primary work cycle. , kneading dehydration, wind blowing dehydration or single and double-sided dehydration, the purpose is to reduce the moisture of the filter cake to the greatest extent.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- How to improve the working efficiency of the filter press?

- Super essential oil filter is easy to operate, safe and low energy consumption

- The difference between high pressure plate and frame filter press and high pressure diaphragm filter press

- What are the factors that affect the use effect of diaphragm filter press

- Advantages of environmentally friendly sewage treatment machines in sewage treatment

- Application of Diaphragm Filter Press in Coal Washing Industry

- How to do a good job of shutting down the filter press?

- Environmentally friendly sewage treatment machines are widely used in all walks of life

- What is the importance of regular maintenance of the diaphragm filter press during use?

- Automatic cake unloading device for box filter press