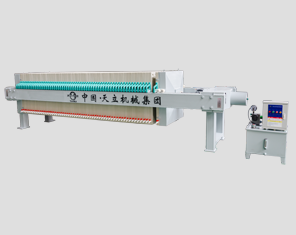

Filter press: It is a kind of intermittent filtering equipment, mainly used for solid-liquid separation. It filters materials through pressure, and is widely used in chemical and pharmaceutical fields. Especially for the separation of viscous and fine materials, it has its own unique characteristics. It is suitable for solid-liquid separation of various suspensions. It has a simple structure and is easy to use. It is widely used in industrial and mining enterprises such as petroleum, chemical industry, metallurgy, pharmacy, sugar refining, mineral processing, food and sewage treatment.

There are many reasons why the filter belt of the automatic filter press is not washed cleanly. If it is a lack of water pressure, it is recommended to replace the pump type. When replacing a high-lift pump, it is recommended to replace the high-flow nozzle to wash the filter belt. It will directly block the holes of the filter cloth, which will seriously affect the water permeability and permeability of the filter belt. Let's see how to do it.

The difference between the automatic filter press and the general filter press is that there are more automatic printing plate pulling systems, automatic liquid receiving and flipping printing plates, automatic cleaning filter cloth and other systems, which make the equipment operation more intelligent and automatic. The structure design of the whole machine Scientific and reasonable, high mechanical strength, stable structure, durable, easy to operate and protect.

Drug residues are generally caused by:

1. When preparing the polymer, the concentration is too high or the drug input is too much.

2. Using a pipeline static mixer, the reaction time of the chemical solution is too short or the contact between the chemical solution and the sludge is insufficient.

3. Because the stirring time of the polymer is too short, the drug cannot be completely dissolved. Generally, after stirring for 30 minutes or longer, the polymer is completely dissolved. If the time is too short, part of the drug will remain and block the filter, and then waste the drug

In addition, the plate and frame filter press is suitable for suspensions with large or almost incompressible filter residue compressibility. The solid particle concentration of the suitable suspension is generally less than 10%, and the operating pressure is generally 0.3 to 0.6MPa. It can reach 3MPa or higher. In order to save costs, some sludge dewatering chambers use manual dosing equipment, the amount of powder added is too much, and the concentration of the drug equipment is too high.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- What should I do if the water seepage between the plate and frame of the filter press is corrected?

- What are the specifications for different filter press specifications?

- Maintenance content of filter press

- Is it harmful for the plate and frame filter press to filter too much?

- The reason and treatment method of the filter plate of the filter press

- The reason for the turbidity of the output of the diaphragm filter press