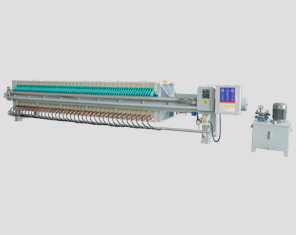

It directly affects the service life of the equipment and the next work efficiency. The shutdown work should not be sloppy. We cannot ignore the follow-up operations, and the operation after the shutdown should be given the same attention as the maintenance.

In fact, it is not so simple. Can the filter press be left after it is stopped. The filter press manufacturer reminds you that the following follow-up operations must be done after the shutdown to ensure the normal use of the equipment next time.

The basic work is to make sure that there is no filtrate in the equipment. 1. When the filter press equipment stops running. It means that no filtrate can be left in the equipment, because the filtrate in the static state is slowly dried in the equipment. When they accumulate, they will form hard solids one by one, which will not only block important parts of the equipment, but may also cause the filter press to not work properly when it is restarted next time, or cause the filter press to burst. The liquid is cleaned from the equipment to prevent it from drying out or chemical changes in the equipment.

How to do a good job of shutting down the filter press?

Because once the filter cloth and the filter press are used together, the filter cloth of the filter press must be kept wet after use. The strong pressure of the filtrate and the equipment can cause subtle changes in the filter cloth. Such a filter cloth can no longer withstand the test of drying, because the drying of the filter cloth will cause the filter cloth fibers to shrink, so that the filter cloth will seriously change the quality of intercepting solid particles, which will seriously affect the filter press. The working quality of the filter press will also make the filter cloth more easily damaged, so the maintenance work of the filter cloth should be done well after the shutdown. Otherwise, the oil will be degraded and corrupted. After the filter press equipment stops running, it is necessary to prevent the hydraulic station from entering the water. .So after the shutdown, the sealing maintenance of the hydraulic station should be done well.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- Environmentally friendly sewage treatment machines are widely used in all walks of life

- What is the importance of regular maintenance of the diaphragm filter press during use?

- Automatic cake unloading device for box filter press

- Failure Analysis in the Application of Fast High Pressure Diaphragm Filter Press

- What problems should be paid attention to when operating a box filter press?

- How does the filter press work?

- What factors will affect the filtration efficiency of a diaphragm filter press?

- How to improve the working efficiency of automatic dismantling plate and frame filter press equipment

- What is the difference between a plate and frame filter press and a box filter press?

- How to tell whether the filter press is running normally from the oil pressure state?