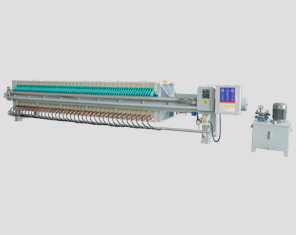

1 Features of fast high pressure diaphragm filter press

(1) Multi-port feeding: The feeding speed is fast and uniform, the filtration cycle is short, and the production efficiency is high, which reduces the possibility of differential pressure inside the filter plate and prolongs the service life of the filter plate.

(2) Multi-cylinder compression: the filter plate is uniformly and reasonably stressed, with good sealing performance and no material spraying.

(3) Diaphragm pressing: 2 times of pressing and dehydration, the moisture content of the filter cake is low, and the cake is good; the filtration cycle is shortened, and the processing efficiency of the whole machine is improved.

(4) Grouping and opening: filter plates are unloaded in groups, with fast speed, short operation time and high production efficiency.

(5) Vibration unloading: relieves the heavy labor of manual feeding.

(6) Automatic control: The monitoring device is used to realize the whole process of automation. (7) Optimal design: small footprint, low power consumption, low noise. (8) Humanized design: with reliable protection device, easy to operate.

2 Composition of the fast diaphragm filter press system

The rapid diaphragm filter press is mainly composed of a frame part, a filter part, a filter plate moving mechanism, a pressing part, a discharge mechanism, a hydraulic system, and an electric control system. The frame is mainly composed of a main beam, a fixed pressure plate, a rear bracket and an auxiliary support The filter part is composed of press filter plate components and filter filter plate components alternately arranged on the main beam, and a layer of filter cloth is covered on both sides of the two filter plates to form filter chambers; the filter plate moving mechanism is mainly composed of Hydraulic motor and drive chain; the pressing part is composed of movable oil cylinder base and slider assembly; the unloading mechanism is composed of 2 vibrating oil cylinders and a swing rod fixed on the filter plate; the hydraulic system includes oil pump, hydraulic control element, hydraulic actuator Components, high-level fuel tanks, etc.; the electric control system consists of electric control cabinet, mechanical action limit switch of filter press, hydraulic station oil pump motor, solenoid valve and slurry compressed air pipeline electric control valve.

3 The working principle of the fast diaphragm filter press The filter press first closes the filter plate through the drive mechanism and the sprocket chain drive, and the filter slurry is filtered from the middle end of the fixed pressure plate through the pipeline under the action of the pump. The feed hole at the upper end of the pressing plate enters the filter chamber. Under the action of pressure, the liquid is discharged, and the solid particles are trapped in the chamber by the filter cloth. air to make the diaphragm produce elastic deformation that squeezes the filter cake direction for secondary dehydration. In order to prevent the unfiltered slurry in the feeding pipeline from entering the conveying system with the filter cake, the compressed air of 016-018MPa is introduced into the pipeline. Return the unfiltered slurry to the slurry sedimentation tank. After the dehydration of the filter cake is completed, the piston rod of the compression cylinder is retracted, and the hydraulic motor in the pulling mechanism drives the sprocket and the chain to move, so that all the filter plates are divided into 3 times Pull open and unload. After the filter cake is removed, spray the filter cloth with clean water with a pressure of 013-015MPa.

4 Failure analysis and solutions in the application process

Hydraulic station failure

(1) The noise of the plunger pump is too large. Solution: First, check the rotation direction of the pump. Loosen the end of the hydraulic pipe connecting the pump outlet and the valve block, and jog the plunger pump. If there is no oil or little oil, Then switch any 2 wires of the motor to make the rotation direction of the pump correct; 2 is to check the bearing of the pump, disassemble the pump body, and replace it if it is found that the bearing is broken or stuck.

(2) The plunger pump starts too frequently. One possibility is due to the leakage of the hydraulic system or the setting of the pressure relief valve in the high pressure section is too low. If the hydraulic pipeline interface leaks oil, replace the sealing ring; If the pressure of the pressure valve is not within the specified range, increase the pressure clockwise to the specified range. Another possibility is that the seal of the oil cylinder is damaged and needs to be replaced in time.

(3) The hydraulic pump cannot reach the required high pressure. First, check whether the hydraulic station is exhausted. If not, exhaust it in time; 2. Check the pipeline interface between the hydraulic station and the cylinder to see if the hydraulic system leaks. Then replace the sealing ring; 3. Check whether the hydraulic pump, hydraulic valve or cylinder seal is damaged, and repair or replace it in time if there is damage; 4. Check the pressure setting value of the high pressure section of the two-stage valve, if it is too low or the valve has If it is damaged, the valve should be reset or repaired according to the hydraulic connection diagram; 5 is to check the pressure relief setting value of the high pressure section, if it is too low, it should be reset according to the hydraulic connection diagram; 6 is to check whether the solenoid valve is damaged and should be replaced ;7 is because the whole set of filter plates is too short, if there is a lack of filter plates, a filter plate should be added or a piston rod should be extended between the compression plate and the cylinder piston rod.

(4) The hydraulic pump cannot supply oil. One may be that the oil level of the oil tank of the hydraulic station is too low, and should be added to the specified oil level; 2 may be that the inlet connection of the hydraulic pump is not tightly sealed, and the sealing device should be tightened; 3 may be the piston The piston of the pump is damaged and needs to be replaced.

(5) The oil supply of the hydraulic pump is insufficient.

First, the oil is too thick, and low-viscosity hydraulic oil should be used;

2. The rotation direction of the oil pump motor is wrong, and the rotation direction should be changed;

3. The two-stage valve setting of the hydraulic pump is too low and should be adjusted to 5MPa;

4. The pump is worn out and needs to be replaced;

5. The set pressure of the pressure relief valve of the hydraulic station is too low, and the pressure relief valve should be reset according to the hydraulic connection diagram.

Pulling system failure

(1) The pull plate cannot be opened. The possible reasons are: ① The light curtain has no signal: check whether someone is overhauling the filter press or whether the line is disconnected, if so, evacuate the person or connect the line; ② The drive motor is damaged: check the motor Whether the wear is serious or the internal oil circuit is opened, if so, replace the motor; ③ The limit switch is damaged: check whether the limit switch of one action on the pull plate is on, if not, replace the limit switch; ④ Execute the pull plate The electromagnetic reversing valve in action is damaged: remove the power head on the hydraulic valve, turn on the hydraulic pump, and make the hydraulic valve pull in. If the plate is not pulled, replace the hydraulic valve; ⑤ The electromagnetic reversing valve coil is damaged: if the hydraulic If the valve is normal, the coil is damaged and the coil needs to be replaced.

(2) The filter plate cannot be moved to the correct position. The reasons are: ① The guide rail of the filter plate suspension mechanism is too dirty, and the guide rail should be cleaned; ② The pull plate chain is too loose or too tight, generally the chain sag does not exceed 2cm after pressing down by hand. ; ③ The pull plate mechanism lacks lubrication, and lubricating oil should be added; ④ The pressure of the hydraulic system is not enough, and it should be adjusted to the specified pressure.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- What problems should be paid attention to when operating a box filter press?

- How does the filter press work?

- What factors will affect the filtration efficiency of a diaphragm filter press?

- How to improve the working efficiency of automatic dismantling plate and frame filter press equipment

- What is the difference between a plate and frame filter press and a box filter press?

- How to tell whether the filter press is running normally from the oil pressure state?

- The use of automatic and semi-automatic pulling plate of Hangzhou diaphragm filter press

- The method to solve the problem of permeability of diaphragm filter press

- 5 major shortcomings of my country's diaphragm filter press that need to be broken!

- Reasons and solutions for the turbidity of the automatic filter press