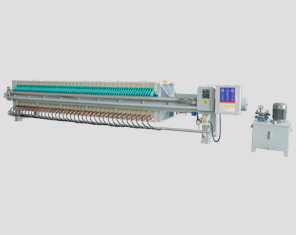

The new automatic cake unloading device is composed of the wheel set part (filter cloth hanger), the rapping part (jitter part), the fine-tuning spring seat part, and the transmission frame part. Form a "person" shape, the filter cloth will pull the filter cake out of the groove of the filter plate, and the cake will fall off depending on the weight of the filter cake. When the unloading of the cake is not sufficient, the shaking mechanism transmits the shaking force to the filter cake, increasing the Shake shearing to achieve reliable unloading. By adjusting the amplitude modulation eccentric block in the shaking mechanism and the pre-tightening force of the fine-tuning spring in the fine-tuning spring seat part, the increase or decrease of the shaking and shearing force is realized.

Its characteristics are as follows: ①The "herringbone"-shaped pulley sliding filter cloth frame is skillfully combined with the shaking mechanism, which strengthens the function of unloading the cake and makes the automatic unloading more sufficient. ②The outstanding advantage of the flexible transmission system is that when the filter plate is pulled diagonally It still does not affect the normal operation of the unloading cake, and it will not cause deformation of other structural parts. It is a highly reliable transmission system. ③ When replacing the filter plate normally, there is no need to disassemble the hinged steel plate, and there is no shielding of the vibrating beam. After moving the flexible wire rope, it can be It is very convenient to hoist the filter plate, which creates good working conditions for maintenance. ④ Taking into account the basic requirement of frequent replacement of filter cloth in daily operation, the innovative design of the tube-type filter cloth rack makes it very convenient to replace the filter cloth. ⑤ Completely Uninterrupted automatic cake unloading is realized, unnecessary manual pauses are removed, and the cake unloading time is reduced from 30 minutes to 20 minutes. ⑥ Workers no longer use cake shovel plates, which eliminates abnormal accidents of puncturing the filter cloth and prolongs the service life of the filter cloth. .⑦After the filter cloth is in the shape of "herringbone", it can not only wash the working surface of the filter cloth, but also wash the residual slurry on the surface of the filter plate to ensure the regeneration of the filter cloth and the smooth passage of the filtrate. ⑧It is easy to modify. The major change is to attach the cake unloading device to the original equipment, and it has a wide range of adaptability and can be used for rubber, polymer, cast iron and other filter plate modifications.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- Failure Analysis in the Application of Fast High Pressure Diaphragm Filter Press

- What problems should be paid attention to when operating a box filter press?

- How does the filter press work?

- What factors will affect the filtration efficiency of a diaphragm filter press?

- How to improve the working efficiency of automatic dismantling plate and frame filter press equipment

- What is the difference between a plate and frame filter press and a box filter press?

- How to tell whether the filter press is running normally from the oil pressure state?

- The use of automatic and semi-automatic pulling plate of Hangzhou diaphragm filter press

- The method to solve the problem of permeability of diaphragm filter press

- 5 major shortcomings of my country's diaphragm filter press that need to be broken!