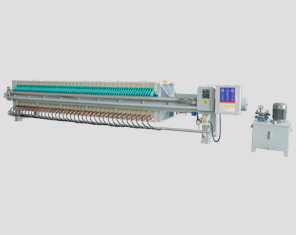

1, semi-automatic pull plate

On the semi-automatic draw plate are the guide rollers for the sidebar of the outer filter press. The shifter is manually positioned by the operator so that the separated slurry is below and between the plates to be separated. Once in position, the operator presses a button, Activate pneumatic operation. The paddles rise between the plates and then extend to separate the plates. The operator releases the button and the paddles retract. Once the operator verifies that the mud has fallen and the cloth is in good condition, the operator moves the plates move to the next board and repeat the process.

2, automatic pull plate

The automatic draw plate is mounted to the side bar and operated with a hand-held control. The shifter allows the filter plate to be easily moved during cleaning. This is especially important when using large thick plate filter presses. The operator will shift the Place the filter on the handle you want to move, then press the shift button, which pushes the plate away from the pack, repeating the process along the pack until the filter press is emptied. Pulling the plate provides easy access during the filter press cleaning cycle One-person operation. This fully automatic pull plate, which functions like a suspension shift, allows the operator to press a button to activate the actuator. Each plate is pushed to the end of the filter press one at a time. The fully automatic pull plate is equipped with a safety shut-off function that will turn off the shifter if someone gets in the way.

A widely accepted remedy for filter press clogging is to use a precoat material on the media prior to solution feed. Commonly used precoat materials are diatomaceous earth and bleached wood pulp. Mix these materials with water in the mud, and recirculated through the filter press until the water is clarified and the media has a precoat.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- The method to solve the problem of permeability of diaphragm filter press

- 5 major shortcomings of my country's diaphragm filter press that need to be broken!

- Reasons and solutions for the turbidity of the automatic filter press

- The application potential of diaphragm filter press in the field of sludge treatment is huge

- Detailed introduction of Tianli machinery ultra-essential oil filter

- Biomass Boiler Boiler Makeup Water Loss

- Does the program-controlled automatic tension plate filter press have automatic pressure maintaining function?

- What is the reason for the overheating of the diaphragm filter press?

- Advantages and disadvantages of plate and frame type, horizontal disc type and candle type diatomite filter?

- What does a filter press do and what are its main features