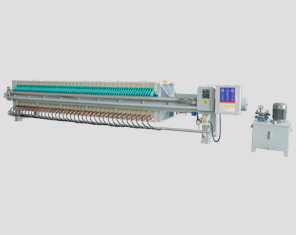

Are the structure and contacts of the filter press control buttons normal?

During the operation of the filter press, the hydraulic system uses the hydraulic oil as the pressure carrier to transmit the internal pressure. Therefore, it can be said that the hydraulic oil directly affects the operating state of the filter press, and its impact on the filter press will directly reflect the processing effect.

As a machine, a filter press needs oil as an auxiliary, including lubrication and transmission effects. The hydraulic oil is the same as a filter press, which not only helps the filter press run better and more smoothly, but also makes the filter press effectively avoid wear and tear .It is an essential oil use for filter press.

There are many types of hydraulic oil for filter presses on the market, and it is true that one can choose the pressure of the hydraulic system, but not all systems with high pressure values require more hydraulic oil. It also depends on the filter press The working principle and internal structure of the machine itself.

The filter press is a high frequency operation for a long time, so the hydraulic system needs to provide a higher pressure for the filter press. Under such pressure, the hydraulic oil is of high resistance type. In addition, it should be considered when selecting hydraulic oil Temperature factor. For example, when the temperature is low, low temperature hydraulic oil should be selected. Since the environment of the filter press is usually harsh, it does not contain a concentration of acid gas, and is full of kerosene, alkaline dust, etc.

In the long run, these caustic chemicals can cause damage to the electrical components of the filter press. It can cause electrical failures, causing the control buttons to become unresponsive. When the filter press has a condition where the control button operation is ineffective, check the filter press first The structure of the machine control button and whether the contact is normal.

Check method: Press the corresponding button and observe whether the corresponding node indicator of the PLC input is lit. If it is lit, the button is not faulty. If the response button is not lit, please check the relevant terminal line.

The operation of the filter press is to generate a strong force on the filter plate through the hydraulic system. Only in this way can the separate filter plate form the necessary part of the operation of the equipment - the filter chamber, that is to say a certain number of filter plates work under strong pressure, when When the pressure inadvertently exceeds the tolerance of the filter plate, the filter plate will naturally rupture and be damaged. When the material is removed, the flange around the filter plate is prone to wear. Once the edge is severely worn, the filter chamber cannot be sealed, and the pressure inside the filter is too high. The liquid will wear out. When leaking or squirting, the filter press will further aggravate the degree of wear of the filter plate during the movement of the liquid, and the result is that the filter plate is completely damaged. Therefore, in order to avoid cracks in the filter plate of the filter press, it is necessary to solve this problem. 2 problems. The user must strictly control the pressure acting on the filter plate, and try not to exceed the size range of the frame filter press design. And try to avoid the edge of the filter plate from wearing.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- The filter cloth of the filter press is not placed correctly, causing water leakage without filtering

- Which method should be used to maintain the filter plate of the filter press

- What is the reason why the filter belt of the belt filter press always deviates?

- Maintenance and protection of vertical presses

- What is the filtration speed, operation method and development direction of the filter?

- What is the principle of the plate and frame diatomite filter to achieve filtration?

- Will the temperature of the filtrate affect the normal operation of the filter press?

- Improvement of the bending direction of the feeding hose of the quick-opening diaphragm filter press

- 3 Factors Affecting Filter Press Performance

- What is the reason for the overheating of the diaphragm filter press?