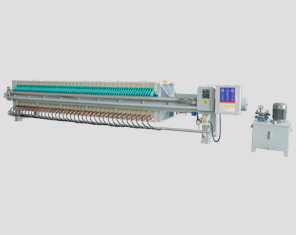

Diaphragm filter press is a basic filter unit that combines the filter frame and filter plate of the plate and frame filter press into one. Compared with the plate and frame filter plate, the diaphragm filter plate has the following characteristics: The structure of the plate is strong, not easy to be damaged, and can withstand higher filtration pressure.

The quick-opening diaphragm filter press adopts the integrated planning and production of machine, electricity and liquid, and consists of 5 parts: frame part, filter part, hydraulic part, discharge mechanism and electrical control part. It can be adjusted according to the number of filter plates. However, it can be changed to form different filtration areas and volumes; the feeding method is 2-head center feeding, which has fast filtration speed, reasonable structure, simple operation, convenient and reliable maintenance; it can complete automatic pressing, pressure maintaining, pressure supplementation, and loosening. Various processes such as pulling the plate. The structural planning features of the diaphragm filter press are as follows:

(1) The filter press structure is improved, and the dehydration function is increased. That is, on the filter press, the initial filtration and dehydration of the high-pressure fluid feed, the filter cake kneading and pressing for 2 times, and the compressed air strong airflow blowing the filter cake 3 times Dehydration.

(2) It can deal with the problem that cavitation is easy to occur due to the low concentration of flotation concentrate and a large amount of foam, that is, the difficulty of pumping the foam pulp to reduce power consumption.

(3) It can overcome the disadvantages of the traditional tailings filter press with large model and slow filtration speed, such as the large size of the single filter cake, not easy to break, and long single cycle time.

(4) It can reduce the moisture of the clean coal and improve the shedding effect of the filter cake.

(5) The filtrate concentration is low and can be directly entered into the circulating water system, which can overcome the shortcomings of the vacuum filter that must return to flotation due to the high filtrate concentration, and then affect the flotation effect.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Why does the motor of the diaphragm filter press make noise?

- What is the reason for the diaphragm filter press spray?

- Weldability and material selection of frame material of diaphragm filter press

- Do you know the entire cleaning process of the filter press?

- How does the filter plate expansion system of the diaphragm filter press work?

- How to do parts inspection for filter press?

- Diaphragm filter press is an ideal equipment for filtration and scrubbing in pigment production

- Why does the diaphragm filter press spray?

- The hydraulic system design of the filter press's operating process includes pipelines and control valves.

- Precautions for the use of filter equipment