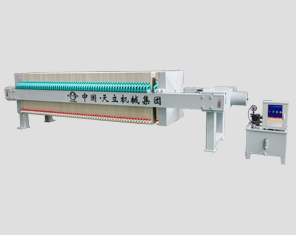

After long-term use of filter press equipment, it is inevitable that parts will be damaged. Although sometimes the damage of parts will not cause equipment failure, there are hidden dangers that you do not know. Therefore, it is recommended that you should Check its parts regularly. The detailed inspection methods are as follows:

1. Inspection method: It is simple and feasible, widely used, and can be divided into:

(1) Visual inspection method: Investigate the parts of the filter press visually or by means of a magnifying glass, and determine the surface damage of the parts such as roughness, grooves, cracks, scratches, peeling (peeling), fractures, and large and obvious deformation of the parts, serious wear and tear , surface annealing and ablation, etc.

(2) Percussion method: For some parts that have no obvious damage, the quality of the parts can be judged by whether the sound is loud or hoarse by percussion.

(3) Comparison method: Compare the new standard parts with the inspected parts to identify the technical conditions of the inspected parts, such as the size of the filter plate handle, the specifications of the filter press nozzle, etc.

2. Measurement method: After the parts of the filter press are worn or deformed, the size and shape will be changed, or the technical performance (such as elasticity) will decrease due to fatigue. It can be measured by measuring tools and instruments and compared with the allowable specifications to determine Whether it continues to be used is still to be repaired or obsolete.

3. Detection method: The detection of hidden defects of filter press parts, especially the slender defects of important parts. It is of great significance to ensure the quality and use of repairs and must be carried out carefully. There are mainly the following methods:

With the above methods, it is possible to check the damage of parts to different degrees, and the use and oldness of parts have an impact on the efficiency and operation of the filter press equipment, especially the important parts, such as filter plates, water nozzles, etc. It directly affects the processing function of the filter press. Therefore, the user should pay attention to the inspection of the filter press parts.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Diaphragm filter press is an ideal equipment for filtration and scrubbing in pigment production

- Why does the diaphragm filter press spray?

- The hydraulic system design of the filter press's operating process includes pipelines and control valves.

- Precautions for the use of filter equipment

- What are the reference specifications for filter press product classification?

- The automatic deviation adjustment of the filter cloth of the filter press is driven by the deviation of the filter cloth to drive the cross adjustment rod to roll.

- Application of filter press in solidification treatment of pile foundation discarded mud

- When the pressure of the filter plate of the filter press is less than the normal number, it is forbidden to start the operation

- Which filter press has the best effect in sludge treatment?

- What are the factors that affect the filtering time of filter equipment?