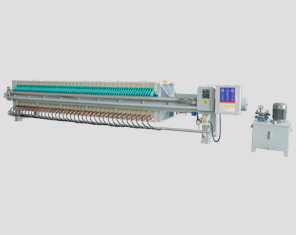

Diaphragm filter presses have been widely used in petroleum, chemical, food, electronics, ceramics, textile and other industries. They are installed in various special places to extract various media that cannot be pumped by conventional pumps. Satisfactory results have been obtained. However, The application potential of pneumatic diaphragm filter press is not known to many people. Diaphragm filter press uses compressed air as the power source. It is suitable for various corrosive liquids, liquids with particles, high viscosity, volatile, Highly toxic liquids can be exhausted.

Different diaphragm filter press housings and different material diaphragms are selected according to different liquid media. Diaphragm filter press housings are: aluminum alloy, PP plastic, ductile iron, stainless steel, etc. Long, etc. to meet the needs of different users. It has been installed in various special places and used to pump media that cannot be pumped by conventional pumps, and all have achieved satisfactory results.

Due to the remarkable characteristics of the pneumatic diaphragm filter press, it has been gradually invading the market of other pumps and occupying a part of it. For example, the diaphragm filter press has occupied a certain dominant position in the fine chemical industry such as paint and coating and the ceramic industry. position, and in some other industries, such as environmental protection, wastewater treatment, construction, sewage and other industries, it is expanding its market share, and has an irreplaceable position for other pumps.

1. Because air is used as power, the flow is automatically adjusted with the change of back pressure (outlet resistance), and the viscosity range of the applicable medium is wide. The working point of the centrifugal pump is set based on water. If it is used for viscosity Slightly higher fluids need to be matched with a reducer or variable frequency governor, and the cost will be greatly improved, and the same is true for gear pumps.

2. The diaphragm filter press can be used to transport fluids with relatively unstable chemical properties, such as: photosensitive materials, flocculation liquid, etc. This is because the shear force of the pneumatic pump is low and the physical impact on the material is small.

3. In the harsh center of the construction site, such as construction sites, industrial and mining wastewater discharge, due to the large amount of impurities and complex components in the sewage, the pipeline is easy to block, which will cause an excessive load on the electric pump, and the motor will be easily damaged by heat. Diaphragm The filter press can pass through the particles and the flow rate is adjustable, and it will stop automatically when the pipeline is blocked until it is unobstructed.

4. In addition, the pneumatic diaphragm filter press is small and easy to move, does not require foundation, takes up very little space, and is cumbersome and economical to install. It can be used as a mobile material conveying pump.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Quick-opening diaphragm filter press structure planning features

- Why does the motor of the diaphragm filter press make noise?

- What is the reason for the diaphragm filter press spray?

- Weldability and material selection of frame material of diaphragm filter press

- Do you know the entire cleaning process of the filter press?

- How does the filter plate expansion system of the diaphragm filter press work?

- How to do parts inspection for filter press?

- Diaphragm filter press is an ideal equipment for filtration and scrubbing in pigment production

- Why does the diaphragm filter press spray?

- The hydraulic system design of the filter press's operating process includes pipelines and control valves.