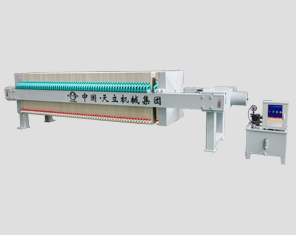

We all know that the filter press is a kind of intermittent operation filtering equipment, which is mainly used for solid-liquid separation. The material is filtered by pressure, and it is widely used in the chemical and pharmaceutical fields, especially for the separation of viscous and fine substances.

In the coastal area where the foundation soil is mainly cohesive soil, sandy soil, silt and silt soil, the wet-worked cast-in-place piles are widely used. However, a large amount of mud will occur during the construction process. Severely pollutes the surrounding soil and environment, and even leads to stagnation of the construction progress and damage to the quality of the project. Therefore, it is necessary to explore and optimize the treatment process of discarded mud.

At present, the harmless treatment method of mud is relatively simple. Generally, it is naturally air-dried after centralized stacking, and a few parts are cured with admixtures, which takes a long time and occupies a large area for consumption. .With the development and application of building technology and construction technology, new technologies such as mud dehydration and solidification process, rapid and harmless treatment are becoming more and more sophisticated.

Among them, filter press is a common equipment used for solid-liquid separation in chemical and pharmaceutical fields. After development and practice, it has also been used in the field of mud solidification in pile foundation engineering.

The industry has proposed a box filter press mud solidification construction method. The method is to send the blended mud into the filter press filter plate for closed pressure, filter cloth filtration, separate solids and liquids, and transport the solid mud cake out. It is a method of discharging clean water to the municipal pipe network nearby after passing the chemical treatment, which can effectively solve the problem of mud transportation and consumption that has plagued construction enterprises for many years.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- When the pressure of the filter plate of the filter press is less than the normal number, it is forbidden to start the operation

- Which filter press has the best effect in sludge treatment?

- What are the factors that affect the filtering time of filter equipment?

- After the diaphragm filter press is normal, the filter plate can be pressed and filtered

- How does the filter press filter cloth automatic cleaning system work?

- Filter press price and selection of filter press accessories

- Analysis of the method when installing environmental protection sewage treatment machine

- Reasons for distinguishing the process of filter press

- What is the reason for the expansion of the filter plate of the diaphragm filter press?

- Why are diaphragm filter presses expensive and cheap?