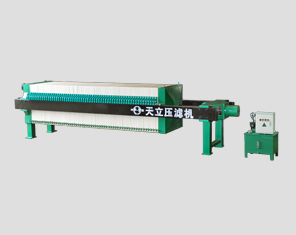

In sludge treatment, the filter press is a kind of dewatering equipment in the filtration industry. Generally, the commonly used filter presses include two types: belt press filter and chamber filter press. So which filter press has the best effect? Press filter, referred to as belt filter press, is mainly composed of driving organization, sludge distribution organization, filter belt, tensioning organization, active deviation adjustment organization, filter belt scouring organization, scraping organization, gravity dehydration area, wedge-shaped dehydration area , press dehydration zone, preferably composed of other components. Its operation filtration is that after the sludge after flocculation treatment enters the sludge distribution tissue, it first passes through the gravity dehydration zone, and the slurry moves together with the filter belt on the filter belt. Under the effect of gravity , the free water is separated from the flocculation, and most of the free water in the filter pulp is removed, and then the filter cake is pressed by several S-shaped pressing rollers in the pressing and dewatering area. Sludge dewatering. Continuous operation of belt filter press, high degree of automation, energy saving, convenient application and maintenance.

Functional advantages:

1. The filter belt is automatically tightened and rectified to solve the problem of damage to the filter belt due to deviation of the filter belt; the electronic control system is equipped with a chain protection device to ensure the reliable operation of the whole machine.

2. Choose a variety of anti-corrosion methods for anti-corrosion and long service life;

3.3 The heavy dehydration area is super long planning, the dehydration rate is high, and the solid content of the mud cake is high;

4. The principle is simple, the components are unified, easy to manage, and easy to maintain;

5. Smooth operation, low noise and less chemical dosage;

6, The speed is fast, the adjustment is fast, and the output is large.

This belt filter press is suitable for sludge dewatering in wastewater treatment processes in urban sewage treatment plants, pharmaceuticals, electroplating, papermaking, leather, printing and dyeing, metallurgy, chemical industry, slaughtering, food, winemaking and environmental protection projects, and can also be used in industrial production. In the case of solid-liquid separation, it is an ideal equipment for environmental management and resource recovery. It can also be used in solid-liquid separation or liquid leaching processes in industrial production. It is widely used in domestic environmental protection projects.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- What are the factors that affect the filtering time of filter equipment?

- After the diaphragm filter press is normal, the filter plate can be pressed and filtered

- How does the filter press filter cloth automatic cleaning system work?

- Filter press price and selection of filter press accessories

- Analysis of the method when installing environmental protection sewage treatment machine

- Reasons for distinguishing the process of filter press

- What is the reason for the expansion of the filter plate of the diaphragm filter press?

- Why are diaphragm filter presses expensive and cheap?

- Why can't the diaphragm filter press filter strong materials?

- What are the reasons why the filter belt of the automatic filter press is not clean?