The environmental protection sewage treatment machine is a device used to treat sewage in life. The small domestic sewage purification biogas digester uses the anaerobic fermentation technology at room temperature, according to the principle of multi-stage artesian flow and gradual degradation, to establish the first-level anaerobic fermentation - the second-level anaerobic fermentation It is a new device for anaerobic digestion and filtration. It consists of anaerobic fermentation, facultative digestion and filtration, sewage return and packing and other processes. The following editor will take a look at the work in this area with us.

1. It is forbidden to process any part of the pump during operation to prevent safety accidents caused by pressure leakage.

2. During the trial operation of the pump and fan, the rotating parts such as the coupling should have a reliable protective cover.

3. After the trial operation, the power supply should be cut off to prevent starting the vehicle under conditions not allowed by the system.

4. For the environmental protection sewage treatment machine, after the trial operation, before the acceptance and handover, special personnel should be designated to take care of it to prevent the loss or damage of spare parts; the pump should be opened by a special driver or a person who plans to understand the function of the pump.

5. Construction workers entering the site must follow the measures and wear qualified protective equipment, helmets, etc.

6. When installing an environmentally friendly sewage treatment machine, during the hoisting process of the equipment, the command should be strengthened to prevent the equipment from bumping. The important equipment is designated to be handled, kept and stored by a special person.

7. It is necessary for electrical equipment to be waterproof and wet.

8. When hoisting equipment with a drive shaft, the drive shaft cannot be used as a lifting point to prevent bearing deformation.

9. When the equipment is hoisted, the wire rope cannot be directly tied to the equipment, and cork should be placed between the wire rope and the equipment to protect the surface of the equipment from damage.

10. The construction site is equipped with fire-fighting equipment of qualified quantity and quality, and no one is allowed to use it for other purposes unless it is urgently needed for fire-fighting.

11. It is necessary to place non-conductive fire extinguishers such as carbon 4 chloride and dry powder in the power distribution room and the centralized location of electrical equipment.

12. It is necessary for welders to strictly implement the operating procedures and the requirements for the use of welding equipment and tools.

13. Before operation, it is necessary to check things carefully, whether the equipment is in good condition and whether the safety device is effective.

14. The length of the primary wire and cable of the electric welding machine is not allowed to exceed 5m, and the distance between the 2 bottles and the open flame is not allowed to be less than 10 meters.

15. After the operation is over, the operation address is sprayed with water, and a special person stays for more than an hour to monitor whether there is any abnormality.

Related News

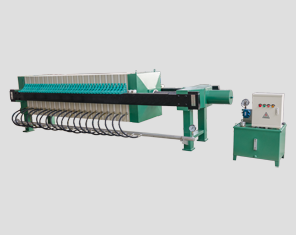

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Reasons for distinguishing the process of filter press

- What is the reason for the expansion of the filter plate of the diaphragm filter press?

- Why are diaphragm filter presses expensive and cheap?

- Why can't the diaphragm filter press filter strong materials?

- What are the reasons why the filter belt of the automatic filter press is not clean?

- What should I do if the water seepage between the plate and frame of the filter press is corrected?

- What are the specifications for different filter press specifications?

- Maintenance content of filter press

- Is it harmful for the plate and frame filter press to filter too much?

- The reason and treatment method of the filter plate of the filter press