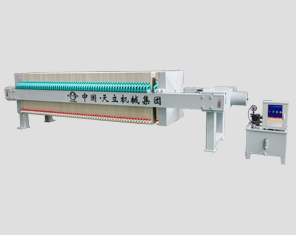

The filter press is used for dewatering treatment of shield piling mud

This year, due to the new crown epidemic, the focus has shifted from export to domestic demand. With the needs of domestic demand transformation, increased investment in infrastructure, such as high-speed rail, subway and other infrastructure has increased. During the construction process, shield machines and pile drivers often A large amount of shield tunneling wastewater and piling mud will be produced. Then appropriate equipment is needed for sewage treatment. For this kind of sludge, due to the different geological structures and strata, the physical properties of its particles will also be quite different. After After years of practice, the plate and frame filter press is a wise choice. It can not only realize the recycling of resources, but also achieve zero pollution.

The system is mainly composed of a filter press system, a dosing system and a feeding system. After the appropriate proportion of the chemicals is added to the sludge, it is metered into the sludge, and mixed and stirred evenly. Then, it enters the filter chamber through the feed pump of the filter press. After high-pressure pressing, a block filter cake is formed. In the whole dehydration process, the following points should be paid attention to. First, the proportion and dosage of the agent should be matched with the sludge. Different soil layers have different viscosity and density, so the amount of the agent The type and dosage will also be different. Commonly used agents include PAC, PAM, lime, etc. In addition, the solid content has a greater impact on the overall filtration efficiency. Generally, the proportion of the feed slurry is more than 1.3. Of course, the premise is to ensure that the material The pulp has good fluidity. Please contact us for the appropriate filter press type and model.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- Talking about the structure of stainless steel filter

- Is the meaning of the existence of the mechanical filter press really as good as it says?

- How a filter press works

- What are the structural characteristics and working principles of the diaphragm filter press when it is applied in the industry?

- Low filter efficiency? These things to keep in mind

- What preparations need to be done before using the rice wine press

- How to effectively extend the service life of the plate and frame filter press?

- Precautions and operation procedures in the use of rice wine press

- What preparations need to be done before using the rice wine press

- How the automatic filter press works