The filter plate is an important part of the filter press equipment. Like the filter cloth, it is easy to wear during use. What is the reason for this phenomenon?

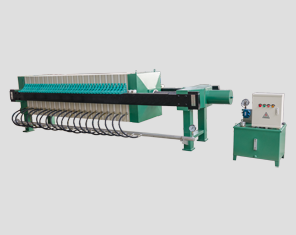

The filter plate of the filter press is made of composite polyethylene plastic material. Such a filter plate can better adapt to the various harsh operating conditions of the filter press, so that the filter press can be used for a long time. Life. The filter chamber of the box filter press is composed of a flat filter plate and a hollow filter frame. The filter cloth is fixed on the plate frame. This is the primary filter press form in the early days, and the filter chamber of the box filter press is It is composed of two adjacent concave filter plates. The main advantage is that it is convenient to replace the filter cloth. The disadvantage is that the power is low, the filtering effect is not good, and the filter plate is easily damaged.

There are many reasons for the formation of the bad plate of the filter press. Here are some common problems. A filter press with an elastic membrane is installed between the filter plate and the filter cloth of the diaphragm filter press. During the use process, when the feeding ends , High-pressure fluid or gas medium can be injected into the diaphragm plate, then the entire diaphragm will rise to press the filter cake, so as to achieve further dehydration of the filter cake, which is commonly referred to as press filtration.

Sludge filter press The plate and frame filter press is suitable for the suspension with high or almost non-compressible filter residue. The solid particle concentration of the suitable suspension is generally below 10 percent, and the operating pressure is generally 0.3-0.6 MPa , especially others can reach 3 MPa or higher. The first is that the filter press is damaged, resulting in uneven force on the filter plate, and the pressure of the filter press itself will crush the filter plate. The damage mentioned here is only in the pressure During the use of the filter, the filter plate is inadvertently deformed by pressure, the height is uneven, or the edge of the filter plate and the height of the boss are inconsistent, or the edge is directly worn, etc. These damaged filter plates are not easy to see. Out of the box, if such a filter plate that looks sick and is not damaged is used together with other filter plates, during the operation of the filter press, the equipment supplies strong pressure to the filter plate, and the time is also very long, so it is inevitable that there will be problems. Many other filter plates are formed or damaged for a long time.

The second is caused by the filtered material of the filter press. A filter press with a layer of elastic membrane installed between the filter plate and the filter cloth of the diaphragm filter press. During the use process, when the feeding ends, the high-pressure fluid or When the gas medium is injected into the diaphragm plate, the entire diaphragm will press the filter cake, so as to achieve further dehydration of the filter cake, which is commonly referred to as pressing filtration. The filter plate of the filter press is easily damaged.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- Pay attention to these points to avoid rupture of the filter plate of the filter press

- Operation after the automatic filter press is stopped

- The role of high pressure diaphragm filter press in chemical fiber wastewater treatment

- Why does the motor of the diaphragm filter press make noise?