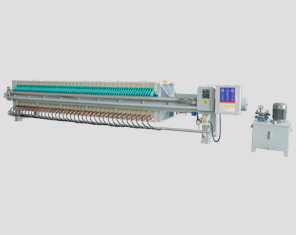

Yellow rice wine press adopts diaphragm inflation pressing

The rice wine press adopts hydraulic pressing, automatic pressure keeping and diaphragm inflation pressing. It is a new product specially developed for the wine industry. The filter cloth is not easy to be damaged, the sealing performance is good, the liquid content of the filter cake is low, the operation is convenient, and the production efficiency is high. Widely used It is used in brewing, pharmaceutical, chemical, food and other industries, especially for the filtration and pressing of rice wine, citric acid, fruit and vegetable juice, soy sauce, industrial glycerin, brewer's yeast mud and other materials.

The main difference between the diaphragm filter press and the ordinary box filter press is that two layers of elastic membranes are installed on the 2 side of the filter plate (the composite rubber membrane is an integral membrane). During operation, when the feeding is completed, the high-pressure fluid medium can be injected into the diaphragm plate. , and then the entire diaphragm will expand and squeeze the filter cake, thereby achieving further dehydration of the filter cake.

The water content of the medium filtered by the ordinary polypropylene filter plate is generally 30%-55% (the physical properties of the high media are different). If the medium filtered by the polymer elastomer is used, the water content will be reduced by 10%-15%.

If the filtered liquid is recycled, the cost of the latter is 15 percent lower than that of the former, and if it is neutral water, it will save more than 10 percent of the water source.

The main products of the company are: reinforced polypropylene box filter press, bearing ultra oil filter, stainless steel chemical centrifugal pump, reinforced polypropylene centrifugal pump, reinforced polypropylene self-priming pump, pneumatic diaphragm pump, self-priming oil pump, hydraulic control valve, etc. "Tianli" brand products are widely used in chemical, environmental protection, pharmaceutical, metallurgy, dyes, food, sugar, brewing, ceramics, electroplating, paper and other industries.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Filter Press Maintenance Tips

- Maintenance and Care of Diaphragm Filter Presses

- Flocculant in filter press sewage treatment

- Filter Press Maintenance Tips

- How to Improve the Working Efficiency of Belt Sludge Filter Press

- An understanding of filter flow and its application

- Share the function introduction of each component of the filter press

- What should I do if the stainless steel filter press runs slowly?

- Automatic components of automatic filter press

- Describe why the plate and frame filter press cylinder does not work in winter