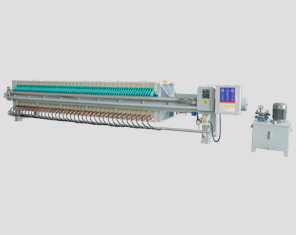

About the filter cloth of high pressure diaphragm filter press

The pressure of the high-pressure diaphragm filter press is insufficient, and the filter plate and filter cloth are under strong pressure, forming a closed filter chamber structure. When the pressure is insufficient, the pressure applied to the filter plate is less than the pressure of the filtrate. When the edge of the high-pressure diaphragm filter press When damaged, even if one side protrudes slightly, even if one side wears frequently, it will come into contact with other filter plates. The final filter chamber will penetrate regardless of the pressure. In this case, we judge from the leak point, the filter plate The penetrating power of the filter is usually very large, and it can even be sprayed, as is the automatic chamber filter press and the horizontal screw discharge centrifuge.

The pressure of the high-pressure diaphragm filter press is insufficient, and the filter plate and filter cloth are under strong pressure, forming a closed filter chamber structure. When the pressure is insufficient, the pressure applied to the filter plate is less than the pressure of the filtrate.

When the edge of the high-pressure diaphragm filter press is damaged, even if one side protrudes slightly, even if one side is often worn, it will come into contact with other filter plates. Regardless of the pressure, the final filter chamber will penetrate. In this case, Judging from the leak point, the penetrating power of the filter plate is usually very large, and it can even be sprayed, as is the automatic chamber filter press and the horizontal screw discharge centrifuge.

High pressure diaphragm filter press

There are many reasons why the filter cloth of a high pressure diaphragm filter press is not properly placed and the filter chamber cannot be sealed. We need to start with a simple filter chamber and see if the filter cloth is wrinkled or the edge of the filter cloth is defective. Due to the The structure is located between the filter plate and the filter cloth, and bears a lot of pressure, so the filter plate is usually less prone to problems, and the rest is the filter cloth.

After the high-pressure diaphragm filter press is normally pressed, the filter plate can be pressed. The pressure and filtration temperature during filtration are within the specified range. If it is too high, it will cause leakage. If the temperature is too high, the plastic filter plate will be easily deformed. The concentration of the suspension should be uniform. Do not mix the chips; after removing the filter cake, rinse the filter cloth and filter plate, leaving no residue on the sealing surface or feed channel, otherwise it will affect the pressure of the platen and the sealing of the filter plate. Since the filter plate The pressure on the 2 sides is unbalanced, which will cause the filter plate to deform.

High pressure diaphragm filter press

The selection of filter cloth for high-pressure diaphragm filter press meets the technical requirements of filtrate filtration. Before installation, the new filter cloth should be shrunk, and the diameter of the opening should be smaller than the diameter of the filter. When the filter plate of the plate and the frame filter plate are matched, The hole and the hole should be relatively concentric. The feeding hole cloth should be tightly attached to the pipe wall, otherwise the filter will not be smooth, the filtration rate will be low, the pipe will be damaged, and the expected filtration effect cannot be achieved. 3-phase decanter centrifuge, automatic pressure Filters are also available.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- The difference between mechanical plate and frame filter press and hydraulic filter press

- 3 factors to reduce the cost of using a filter press

- Advantages of environmentally friendly sewage treatment machines in sewage treatment

- The filter press is used for dewatering treatment of shield piling mud

- Talking about the structure of stainless steel filter

- Is the meaning of the existence of the mechanical filter press really as good as it says?

- How a filter press works

- What are the structural characteristics and working principles of the diaphragm filter press when it is applied in the industry?

- Low filter efficiency? These things to keep in mind

- What preparations need to be done before using the rice wine press