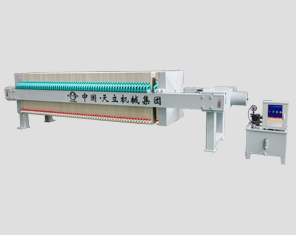

Explain the specific maintenance methods of the filter plate of the filter press. The use of filter press in water treatment is more and more popular, but the filter plate is easily damaged when used for a long time. Which method should be used for maintenance?

1. The filter plate of the filter press cleans the grooves and leaks out the new surface. Clean it with a small saw blade.

2. The ratio of non-repairing agent to the filter plate of the filter press is 1:1.

3. Apply the prepared patch to the grooves, and then add a little more.

4. Quickly put the filter cloth on the filter plate of the filter press, knead the filter plates together to make the repair agent and the filter cloth stick together, and knead the grooves at the same time.

5. After a period of time, the viscose of the filter plate of the filter press will naturally form and will not change. At this moment, it can be used normally.

Caused by the filter material, the filter contains hard, bulky solid particles, which may also cause the filter plate of the filter press to break easily. During the filtration process, such hard solid particles will accumulate in the chamber. With the solid particles With the addition of various hard particles, all kinds of hard particles are piled together, and the filter press automatically provides filter plates. Everyone knows that the force of kneading the filter cake is mutual, and the uneven distribution of hard particles in the filter chamber will also cause pressure. The filter plate of the filter is easily damaged.

The filter press is damaged, resulting in uneven force on the filter plate, and the pressure of the filter press will damage the filter plate. The damage mentioned here is only in the process of using the filter press, and the filter plate inadvertently deforms the filter plate and becomes uneven Or the edge heights of the filter plate and the boss are different, or the edge is directly worn, etc. These damaged filter plates are not easy to see. If a filter plate that looks dirty and not damaged is used, the equipment will be provided during the operation of the filter press. Powerful filter plate. High pressure and long time, so it will inevitably cause a large number of other filter plates or damage for a long time.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- What are the factors that affect the filtering time of filter equipment?

- How to indicate the type of filter cloth?

- Welding Distortion Control and Prevention of Diaphragm Filter Press Frame

- Talking about the effect of the hydraulic system of the filter press on the whole system

- What are the key factors in the disposal of drilling fluids in a diaphragm filter press?

- How to use bag filter device in filter equipment

- What are the reasons for the lack of pressure when the special equipment for stainless steel filter press cannot be pressed?

- Advantages and disadvantages of choosing diaphragm pump or screw pump for filter press

- The difference between plate and frame filter press and diaphragm filter press

- Do you know the entire cleaning process of the filter press?