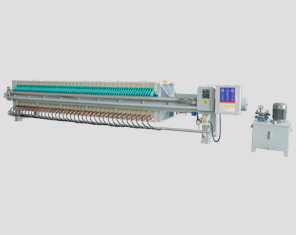

Diaphragm filter press has the advantages of high pressing pressure, good corrosion resistance, convenient maintenance, safety and reliability, etc. It is the first choice for customers in metallurgy, gas, papermaking, coking, pharmaceutical, food, brewing, fine chemical and other industries. Among all manufacturing components, the function of the filter press frame is to support and constrain the filter organization, so that the filter organization can meet the functional requirements of filtering, pressing, washing the filter cake, etc. The frame is the basic part of the filter press, and the 2 heads are The head equipment, the tail equipment and the moving plate are connected by the beams on the two sides, and the beams are also used to support the filter plate equipment and the moving plate equipment.

The quality of the welded seam plays a decisive role in the whole welded structure. For welded structures and components, the residual stress will not only reduce the stiffness and stability of the structure, but also seriously affect the structure under the combined action of temperature and medium. Fatigue strength, resistance to brittle fracture, resistance to stress corrosion cracking and high temperature creep cracking. Because of the existence of residual welding stress, the stress concentration sensitivity of the structure at the welded joint is increased, and the sensitivity of hydrogen embrittlement and cracking is increased, resulting in structural Decreased security and longevity of service.

During the manufacturing process of the frame, when the low alloy plate is CNC or semi-automatic blanking, segmented cutting and slow cooling are selected to ensure that the welding deformation of the material is controlled within a small range. During the assembly welding, the groove can be processed and manufactured. Tooling fixtures, using methods such as anti-deformation and appropriate welding sequence, and comprehensively controlling process parameters such as pre-welding preheating, interpass temperature, welding heat input, post-welding, and post-weld heat treatment to reduce welding deformation of components. Deformation can choose mechanical correction method or heating correction method.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- Talking about the effect of the hydraulic system of the filter press on the whole system

- What are the key factors in the disposal of drilling fluids in a diaphragm filter press?

- How to use bag filter device in filter equipment

- What are the reasons for the lack of pressure when the special equipment for stainless steel filter press cannot be pressed?

- Advantages and disadvantages of choosing diaphragm pump or screw pump for filter press

- The difference between plate and frame filter press and diaphragm filter press

- Do you know the entire cleaning process of the filter press?

- What should I do if the filter press control button does not respond?

- What is the filtration principle of the filter?

- What should we pay attention to in the use of the filter?