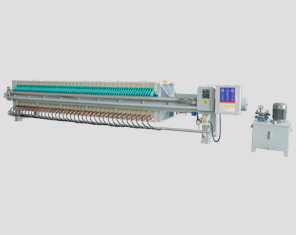

Analyze the heating problem of the diaphragm filter press

In the normal use of the diaphragm filter press, the hydraulic system will generate heat. Generally speaking, this heat generation will not affect the use of the filter press. Next, our filter press editor will analyze the formation of the diaphragm filter press. Causes of overheating and how to deal with it.

We know that compared with the box filter press, the diaphragm filter press generally bears higher pressure, so it has higher requirements for the hydraulic system. On the one hand, the flow rate is larger and the pressure is higher. On the other hand, the power of the oil pump is also The hydraulic system of the filter press is closely related to the temperature. When the hydraulic station is running, the oil pump runs at a high speed and the pressure is high, and the oil temperature will rise to a certain extent. For a normal filter press The hydraulic system generally does not affect the actual use. For large hydraulic systems, the temperature can be controlled by installing a heat sink, so that the filter press can operate normally. Our hydraulic system has a unique oil circuit design, energy saving and environmental protection. heat phenomenon, to ensure stable operation.

However, if the hydraulic system is overheated due to the following reasons, it needs to be repaired in time. We know that the hydraulic system generally enters an automatic pressure-holding state after reaching the set pressure, and the oil pump will automatically stop running. But if the oil pump keeps working, then This phenomenon is accompanied by overheating of the hydraulic system, so it may be caused by the following reasons: the pressure-holding valve is blocked. This is a common reason. The pressure-holding valve is also called a one-way valve. function, which causes the motor to run all the time. Generally speaking, the valve body itself has a long life without quality problems. It is very likely that the oil quality is poor, and there are solid impurities in the hydraulic oil. Therefore, normal use can be restored after cleaning. .

Once you find that the filter press is overheated, you should find out the cause and solve it in time. If you need filter press maintenance, you can also contact us.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Facing the high temperature in summer, what are the good secrets of "heat escape" for filter press equipment

- What should I do if the end of the thrust plate of the high pressure diaphragm filter press is not easy to be compressed?

- What's the matter with insufficient oil pressure in the filter press?

- What should we pay attention to when cleaning the filter?

- How to choose the filter area of stainless steel bag filter

- The importance of filter press manufacturers in water quality treatment

- Why can't filter press filter too hard substances?

- What are the characteristics of stainless steel filter press?

- Are the structure and contacts of the filter press control buttons normal?

- The filter cloth of the filter press is not placed correctly, causing water leakage without filtering