Installation and commissioning of filter press

1. The filter press should be installed on a flat concrete foundation. The thrust plate foot at the feed end is fixed on the foundation with anchor bolts; there is no anchor bolt at the end of the bracket, or two nuts are used to lock the anchor bolt after positioning, There is a proper gap between the nut washer and the foot seat, so that the foot can be slightly stretched. Before positioning, the installer should correct the verticality of the beam and the large plane of the thrust plate.

2. The foundation structure is designed by the construction engineer according to the equipment load, and the anchor bolts with reserved holes should be grouted twice.

3. There should be enough space for operation and maintenance around the filter press, and the hydraulic filter press should choose a suitable location to place the hydraulic station to ensure that the hydraulic station can work normally.

4. Place the filter plate according to the work needs, and arrange the feeding, flushing and drainage pipes. Equipped with a filter pressure indicator and a return channel to control the filter pressure. If it is a diaphragm extrusion type, set compressed air pipeline.

5. Pour clean 20-40 hydraulic oil into the oil tank of the hydraulic filter press, and the operating temperature is amp;gt;:-5 degrees Celsius; if the ambient temperature is low, you can choose a hydraulic oil with a similar viscosity and a low freezing point. The hydraulic oil must be Add through 80-100 mesh sieve.

6. The mechanical or hydraulic device connected to the power supply and the starter motor should work normally. When the hydraulic pressure is pressurized, the pressure gauge should rise steadily, and the hydraulic system should have no leakage. The working pressure of the hydraulic station should be adjusted correctly according to the size of the model. If debugging The fuel tank is found to be insufficient and should be replenished.

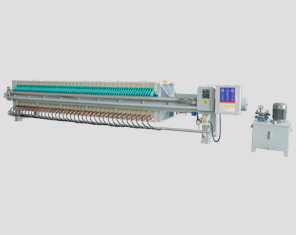

Main products of Tianli Machinery Group: Reinforced polypropylene box filter press, bearing super oil filter, stainless steel chemical centrifugal pump, reinforced polypropylene centrifugal pump, reinforced polypropylene self-priming pump, pneumatic diaphragm pump, self-priming oil pump, hydraulic control Valves, etc. "Tianli" brand products are widely used in chemical, environmental protection, pharmaceutical, metallurgy, dyes, food, sugar, brewing, ceramics, electroplating, paper and other industries.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Yellow rice wine press adopts diaphragm inflation pressing

- Why frontline workers say diaphragm filter presses are better

- Yellow rice wine press adopts diaphragm inflation pressing

- Filter Press Maintenance Tips

- Maintenance and Care of Diaphragm Filter Presses

- Flocculant in filter press sewage treatment

- Filter Press Maintenance Tips

- How to Improve the Working Efficiency of Belt Sludge Filter Press

- An understanding of filter flow and its application

- Share the function introduction of each component of the filter press