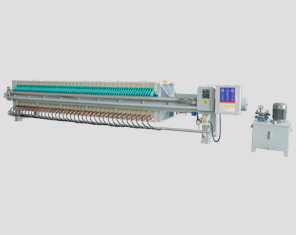

Diaphragm filter press is the most important filtration equipment in industrial production. It is mainly used for solid-liquid separation of materials. We know that diaphragm filter press has a certain operation process in production. According to the correct operation process, diaphragm filter press can be guaranteed. In actual production, if the operation is not correct, the diaphragm filter press will easily explode, which will seriously affect the economic benefits of the enterprise. Heavyweight.

Blasting means that when the mixed concentration of explosive substances and oxygen reaches the blasting limit range, if there are explosive substances, blasting will occur. During the operation of the diaphragm filter press, some explosive substances react with oxygen, and when there is an open flame, mechanical sparks, etc. When the source is ignited, it will cause the diaphragm filter press to explode. Therefore, during the operation of the diaphragm filter press, it is necessary to do a good job in the inspection of the surrounding environment to prevent the oxidation of the blasting material.

First of all, during the operation of the diaphragm filter press, it is necessary to prevent or minimize the possibility of leakage of flammable and explosive substances, and provide a safe operating environment for the diaphragm filter press.

Secondly, it is not necessary or as little as possible to use electrical components that are prone to sparks to effectively prevent the generation of ignition sources of the diaphragm filter press.

Then, nitrogen filling and other methods are adopted at the site of the diaphragm filter press to maintain an inert state, reduce the oxidation of explosive substances, and prevent the occurrence of blasting accidents.

The above is an analysis of the reasons for preventing the explosion of the diaphragm filter press. Through today's study, the diaphragm filter press enterprise should pay attention to the above safety matters in the future production, and eliminate the occurrence of the explosion of the diaphragm filter press from the source. At the same time , During the use of the diaphragm filter press, it is necessary to do a good job in cleaning the equipment, pay attention to the cleaning of the surrounding environment, and create a safe operating environment for the diaphragm filter press.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- The pressure of the hydraulic oil of the high-pressure diaphragm filter press is mainly used as the carrier to transmit the internal pressure

- Working cycle mechanism of automatic filter press

- The advantages of diaphragm filter press in filtration

- Quick-opening diaphragm filter press structure planning features

- Why does the motor of the diaphragm filter press make noise?

- What is the reason for the diaphragm filter press spray?

- Weldability and material selection of frame material of diaphragm filter press

- Do you know the entire cleaning process of the filter press?

- How does the filter plate expansion system of the diaphragm filter press work?

- How to do parts inspection for filter press?