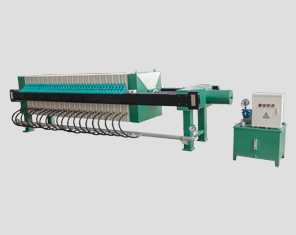

In the process of using a high-pressure diaphragm filter press, the pressure of hydraulic oil is mainly used as a carrier to transmit internal pressure. Hydraulic oil also directly affects the work and operation of the machine, and directly reflects the filtering effect. However, many people do not know the use of hydraulic oil. Due to the requirements of the filter press, the metering method is often selected blindly, which not only affects the long-term protection of the membrane filter press, but also causes damage and adhesion inside the machine.

The mechanical operation of the high-pressure diaphragm filter press requires oil as an auxiliary. It may be lubrication or gearbox. The hydraulic oil is the same as the high-pressure diaphragm filter press, which can not only help the dust collector run better and more smoothly, but also make the dust collector Fast operation. In order to prevent wear, it is very important to use oil as equipment. There are many types of hydraulic oil for high pressure diaphragm filter presses on the market.

When choosing, people will choose from the pressure of the hydraulic system. This is correct, but not all hydraulic oil required by the high pressure value system. Need to pay attention to the working principle and internal structure of the membrane filter press. Now, the high pressure diaphragm pressure When the filter press is sold, it usually communicates directly with customers and introduces auxiliary hydraulic oil. The high-pressure diaphragm filter press not only reduces the blindness of customers who purchase hydraulic oil, but also greatly improves the matching effect, and then increases the high-pressure diaphragm filter press. the service life of the machine.

Sludge pumps and chemical liquid pumps should use screw pumps instead of centrifugal pumps

The sludge pump of the high-pressure diaphragm filter press sludge dewatering system uses a mud pump (a centrifugal pump). During operation, the pump will not block the mud or the pump will leak. During operation, it is generally necessary to flush and repair the pump The workload of the pump is also very large. Through technical research and practical operation tests, it is found that the use of screw pumps to transport sludge has the advantages of stable flow, stable pressure and no leakage.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- Working cycle mechanism of automatic filter press

- The advantages of diaphragm filter press in filtration

- Quick-opening diaphragm filter press structure planning features

- Why does the motor of the diaphragm filter press make noise?

- What is the reason for the diaphragm filter press spray?

- Weldability and material selection of frame material of diaphragm filter press

- Do you know the entire cleaning process of the filter press?

- How does the filter plate expansion system of the diaphragm filter press work?

- How to do parts inspection for filter press?

- Diaphragm filter press is an ideal equipment for filtration and scrubbing in pigment production