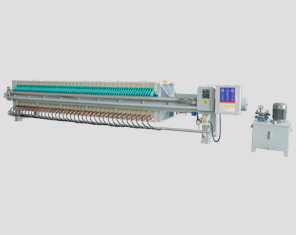

1. Only routine debugging can be performed on the concrete sewage filter press. Before each shift, the entire machine should be fully inspected. The mechanical pressure transmission components and reducer must be filled with lubricating oil. The hydraulic compression should check the oil storage capacity of the oil tank and the hydraulic station. Working pressure. Hydraulic oil is usually replaced once a year, and the hydraulic system should be cleaned once during the replacement. It is less than the working pressure of the cylinder, but not less than the allowable value of the filter pressure. Too small will cause a lot of leakage and damage machine parts.

2. When the filter plate is less than the specified number, it is forbidden to leave the factory to avoid damage to the machine parts. Check the placement of the filter plate before feeding, and the filter cloth should not be folded to prevent a lot of leakage. After the filter cake is unloaded, the filter plate must be placed closely.

3. The filter pressure and filter temperature must be within the specified range. If the filter pressure is too high, it will cause leakage. If the filter temperature is too high, the plastic filter plate will be easily deformed, and the suspension will be suspended during the feeding process. Make the concentration Evenly. There should be no impurities. After the filter cake is unloaded, the filter cloth and filter plate must be washed clean, and do not let the residue stick to the sealing surface or the feed channel, otherwise it will affect the lubrication of the feed and the sealing of the filter plate. This will result in a 2-sided filter plate. Unbalanced pressure will cause deformation and damage to the filter plate.

4. The selection of the filter cloth must meet the filtration technical requirements of the filter plate. Before opening, the new filter cloth should be shortened.

5. In the initial stage of the filter press, the concrete sewage filter press is cloudy. When the filter cloth forms the filter cake layer, the filtrate will become clear. If the filtrate is cloudy or clear mixed, it may be that the filter cloth is damaged or The filter cloth hole deviates from the plate hole. At this point, close the valve or stop the feed and replace the filter cloth. A small amount of leakage caused by the capillary phenomenon of the filter cloth is allowed between the filter plates.

6. When moving the filter plate, the force should be uniform and appropriate, and no collision or beating is allowed, so as not to damage the sealing surface and the handle of the filter plate wrench. After using the filter cloth for a period of time, it will become hard and its performance will decline. Therefore, it is necessary to Check regularly. If any changes are found to affect the filtration speed, neutralization and cleaning can be carried out with the corresponding concentration of weak acid and alkali to restore the function of the filter cloth. If it cannot be restored, please replace it in time.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- What is the filtration principle of the filter?

- Why ensure the cleanliness of the filter oil?

- Introduction to the use of diatomite filter

- Overheating of the diaphragm filter press will damage the filter plate Overheating of the diaphragm filter press will damage the filter plate

- Knowledge about the details of the diaphragm filter press

- Precautions for the use of filter equipment

- Notes on the use of filter equipment

- How does the filter press equipment perform automatic cleaning

- What is the composition basis of vertical press

- Conventional Drainage Methods for Diaphragm Filter Presses