In industrial production, filtering refers to the whole process of separating solid and liquid based on a substance, which is called filtering.

Common filter substances in industrial production: textile substances, granular substances, porous media porcelain substances. Coal mine vacuum filtration machinery and equipment can be divided into 2 categories: disc type vacuum filtration machinery and equipment and drum type vacuum filtration machinery and equipment. It can also be used to filter the coal by flotation, and it can also be used for the coal dust or flotation tailings.

Among them, filtering is a kind of processing technology that extracts solid particles floating in liquid or vapor. Its basic concept: under the effect of pressure difference, the liquid (or vapor) in the mixed liquid passes through the permeable material (filtered material), The solid particles are retained by the substance, thereby completing the separation of liquid and solid.

1) The 2 criteria that the completion filter has:

①Have the necessary equipment to complete the separation process;

②A certain pressure difference (driving force) must be maintained between the two sides of the filter substance.

2) Common filtering methods can be divided into several categories: force filtering, vacuum filtration, pressure charging and centrifugal filtering.

The pressure difference of the force is generated by the aspect ratio of the slurry column; the driving force of the vacuum filtration is the vacuum pump source.

3) The filter has the characteristics: in essence, the filter is the whole process of the multi-component liquid based on the movement of the porous medium.

①The liquid belongs to the ultra-slow activity, that is, the seepage movement, according to the activity of the porous medium. There are two influencing factors, one is the hydrodynamic factor of the macro economy, and the other is the external economic physics factor.

(2) The solid particles 5 in the mixed liquid are continuously accumulated in the porosity of the material or on the surface of the material, so the frictional resistance of the filter continues to increase during the whole process of the filter.

4) Classification of filtration: Dividends are divided into 2 categories, each of which is: cake filtration and deep filtration. The filter cake filtration uses a surface filter. During deep filtration, solid particles are trapped in the porosity inside the material.

5) Filter cake filtering and deep filtering:

①Filter cake filtration generally has a higher concentration value of the mixture, and its volume concentration value is often higher than 1%. If a coagulant is added to the slurry, some lower concentration mixtures can also use filter cake filtration.

②Deep-level filtration mostly separates fine solid particles from very dilute mixed liquid, so it is generally used for liquid purification treatment. Under the condition of similar high efficiency, the starting and ending working pressure of deep-level filtration equipment is generally higher than that of surface area filters. And as the collected particulate matter increases, its gas pressure will gradually increase.

6) The purpose of filtering: It depends on the filter manufacturer to buy the solid phase with use value, or to obtain the high-efficiency liquid phase with use value; or both, or both are discarded as waste.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

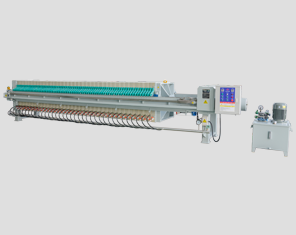

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- What should we pay attention to in the use of the filter?

- The solution to the poor sealing of the filter chamber of the filter press

- Diaphragm filter press filter plate structure improves the travel of the filter plate of conventional box filter presses

- What is the reason for the wear of the filter plate of the diaphragm filter press?

- Pay attention to these points to avoid rupture of the filter plate of the filter press

- Operation after the automatic filter press is stopped

- The role of high pressure diaphragm filter press in chemical fiber wastewater treatment

- Why does the motor of the diaphragm filter press make noise?