What is the filtering principle of the filter

Filtration refers to the whole process of solid-liquid separation according to a certain substance in industrial production, which is called filtration.

Common filter materials in industrial production: textile materials, particulate materials and porous media ceramic materials. Coal mine vacuum filtration machinery and equipment can be divided into 2 categories: disc vacuum filtration machinery and drum vacuum filtration machinery. The key is filtration and flotation. Coal, also filter pulverized coal or flotation tail coal.

Filtration is a processing technology that extracts solid particles floating in liquid or vapor. The basic concept is: under the action of pressure difference, liquid (or vapor) in mixed liquid passes through permeable material (filter material), solid particles It is retained by the material to complete the liquid-solid separation.

1. There are 2 criteria to complete the filtering:

(1) Have the mechanical equipment required to complete the separation process;

(2) Maintain a certain pressure difference (driving force) on the 2 side of the filter material.

2. Common filtration methods can be divided into several types: forced filtration, vacuum filtration, pressure filtration and centrifugal filtration.

The pressure difference of the force is generated by the aspect ratio of the slurry column; the driving force of the vacuum filtration is the vacuum pump source.

3. Characteristics of filtration: In essence, filtration is the whole process of multi-component liquid flowing through porous media.

(1) According to the flow of porous media, the liquid belongs to ultra-slow flow, that is, seepage movement. There are two influencing factors, one is the macroeconomic hydrodynamic factor, and the other is the external economic physical factor.

(2) The solid particles 5 in the mixed liquid are continuously accumulated in the internal pores of the material or the surface layer of the material, so the filtration friction resistance increases continuously during the entire filtration process.

4. Classification of filtration: It can be divided into 2 categories: filter cake filtration and depth filtration. The filter cake is filtered with a surface filter. During depth filtration, solid particles are trapped in the pores inside the material.

5, filter cake filtration and depth filtration:

(1) Filter the filter cake. Generally, the volume concentration of the mixed solution with higher concentration value is often higher than 1%. If a coagulant is added to the slurry, the filter cake can also be used to filter some mixed solutions with lower concentration.

(2) After depth filtration, fine solid particles are separated from the extremely dilute mixed liquid, which is generally used for liquid purification treatment. Under similar high efficiency, the opening and closing working pressure of the depth filtration device is generally higher than that of the surface area filter. Its gas pressure will gradually increase with the increase of collected particles.

6. The purpose of filtering: rely on the filter manufacturer to obtain a solid phase with use value, or obtain a high-performance liquid phase with use value; or both, or both are discarded as waste.

(1) The entire filter cake filtration process cannot be reduced

The filter cake cannot be reduced: when the filter cake is filtered, the liquid passing through the filter cake will generate drag stress on the solid particles according to the conveying volume of the surface layer. It is constructed under the action of the accumulated drag stress here, the particles do not move with each other, and the porosity of the anaerobic granular sludge does not cause transformation, so this filter cake is said to be unable to shrink.

The reason why filter manufacturers can compress the filter cake in production is because: ① In fact, there are few single particles in the slurry, but there are often clusters of different levels, and the cluster pages cannot withstand the liquid drag stress and cause the filter cake to deform ;2-10 micron particles basically have a salt film on the surface, which will cause deformation under the action of liquid; 3. The cohesion or floc of solid particles under the action of coagulant or coagulant has only a small resistance to cutting, and it is It is easy to cause deformation under the action.

Related Industry Knowledge

- Daily maintenance and maintenance of vertical presses

- Application scope and characteristics of soy sauce press

- Principle of diatomite filter and maintenance guide of filter lubrication system

- The understanding of the nominal flow of the filter and its application

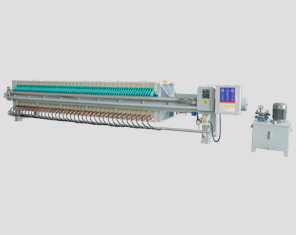

- Diaphragm filter press hydraulic device adopts double cylinder and screw extension structure

- Rice wine press by maintenance and preventive measures

- Daily maintenance and maintenance of plate and frame filter press

- Features of automatic filter press

- Diatomite filter operation method and application

- Working principle and characteristics of stainless steel press

- How to Improve the Working Efficiency of the Plate and Frame Filter Plate of the Filter Press

- What should I do if the pressure of the filter press is not enough?

- Causes of Corrupted Filter Configurations

- How does the filter plate expansion system of the diaphragm filter press work?

- When the pressure of the filter plate of the filter press is less than the normal number, it is forbidden to operate

- Method for dosing and running of environmental protection sewage treatment machine

- Precautions for the use and maintenance of concrete sewage filter press

- What is the filtration principle of the filter?

- Why ensure the cleanliness of the filter oil?

- Introduction to the use of diatomite filter