What is the impact of the working cycle of the diaphragm filter press?

After the diaphragm filter press has been used for a period of time, it always feels that the processing speed will become slower and slower. Many customers are very worried, but do not know what is the cause. As a result, new filter cloths are replaced and the cost is increased. Today's analysis of breaking the door shows the impact Reasons for the periodicity of diaphragm filter presses.

1. Check whether the impeller of the transfer pump is worn. The working principle of the diaphragm filter press is to pump the sludge into the filter press through the flow of the transfer pump. The pore size of the cloth is trapped in the filter chamber of the filter press, slowly forming a lumpy mud cake. The sewage flows out of the equipment through the filter cloth and the sludge layer along the outlet channel of the sludge filter press. After a period of operation, the sludge press filter The impeller of the pump will be worn, which will directly affect the flow and head of the pump, thereby increasing the working cycle of the filter press.

2. Check whether the pipe of the sludge filter press is blocked by solids. Some plastic products sometimes enter the pipe of the filter press with sludge and block the pipe. This directly affects the flow of the sludge pump and reduces the water inflow. Thus affecting a cycle of operating hours.

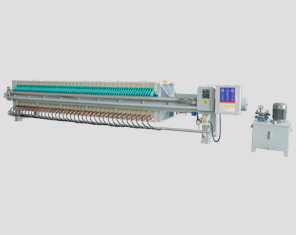

Diaphragm filter press filter plate is made of pure polypropylene by one-shot injection molding. Diaphragm filter plate is composed of 2 diaphragms made of polypropylene and thermoplastic elastomer (TPE) and a hollow box that is hot-pressed into filter plate. Synthetic rubber is also used As the elastic membrane of the diaphragm of the diaphragm filter plate. The plate. In order to ensure that the diaphragm of the diaphragm filter plate is pressed by the material for the second time, the internal pressure is filled with pressurized water or compressed air, without cracking and pressure relief, not only high temperature and high pressure are required The compression process of the filter press. And it takes a long time to use the box filter to cool and relieve the internal stress. Therefore, different materials, structures and corresponding high-strength conditions are designed, so the cost of the diaphragm filter press is higher than that of the same capacity. Chamber filter press.

3. Check the filter cloth of the diaphragm filter press. The filter cloth is a consumable item and needs to be cleaned regularly. In the sludge dewatering operation of the diaphragm filter press, the moisture content of the mud cake is often very high, which causes the mud cake to be turbid during the outbound transportation. Seriously, it affects the environment and does not meet the environmental protection requirements. One of the main reasons found by the technicians is that the filter belt is not completely flushed, and there is blockage, resulting in blockage of drainage and high moisture content in the mud cake. When the flushing water pressure in the filter belt is from 0.6Mpa Increase to 0.8Mpa, and when the flushing water pipe is installed before the filter belt enters the gravity dewatering zone, the dewatering effect of the sludge is improved, and the water content of the mud cake increases and decreases.

Related News

- Filtration principle and operation of plate and frame filter press

- Different matters that should be paid attention to in the use of the filter plate of the diaphragm filter press

- What is the influence of the working period of the diaphragm filter press?

- The reason for the leakage of the box filter press

- Filter bag replacement and pressure condition of super essential oil filter

- The particularity of filter cloth used in plate and frame filter press

- What is the pressing principle of the diaphragm filter press?

- Introduction to filter maintenance

- What is the filtration speed, operation method and development direction of the filter?

- What is the impact of pump selection and insufficient pressure in filter presses?

- How to judge the filterability of a filter press

- How to increase the working efficiency of the plate and frame filter plate of the filter press

- Advantages of Diaphragm Filter Press in Industrial Filtration

- Installation and commissioning of filter press

- Yellow rice wine press adopts diaphragm inflation pressing

- Why frontline workers say diaphragm filter presses are better

- Yellow rice wine press adopts diaphragm inflation pressing

- Filter Press Maintenance Tips

- Maintenance and Care of Diaphragm Filter Presses

- Flocculant in filter press sewage treatment